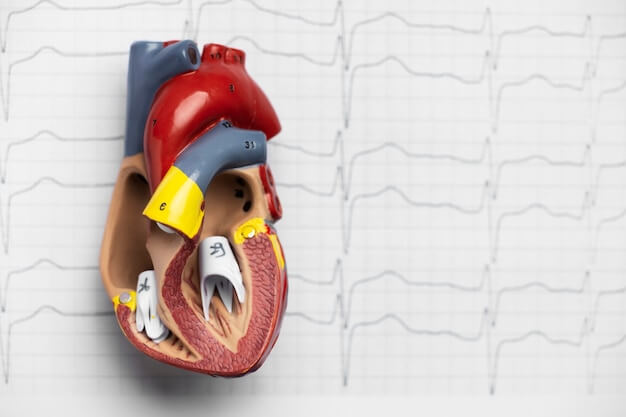

It is reported that researchers from Georgia Institute of Technology and Piemonte Heart Institute are using customized 3D printed heart valve models based on patients' heart CT scanning to improve the success rate of transcatheter aortic valve replacement (TAVR) surgery. Their aim is to avoid perivalvular leakage. This research has been published in JACC: Cardiovascular Imaging.

Perivalvular leakage is a relatively rare complication of TAVR. In TAVR surgery, if the valve replacement is not appropriate, this symptom will occur, which is manifested as blood leakage between the heart tissue and the implanted valve, and ultimately leads to an earlier death of the patient.

"Our idea is that since we can use tissue simulation 3D printing technology to make a customized model for the patient, we can test how well the artificial valve matches the 3D printing model, and then see whether it can predict blood leakage," the researcher explained.

"In the preparation stage of valve replacement surgery, cardiologists have evaluated and predicted various clinical risks, but our 3D printing model provides a quantitative method to evaluate the matching degree between artificial valves and patients."

The researchers used a multi material 3D printer to print the heart valve, so that they could control the "diameter and bending wavelength" of the printing material, so that the model could better simulate the physiological characteristics of the tissue. The model can even show special cases such as calcium deposition, a common underlying factor in aortic stenosis. The researchers said that the performance of these 3D printed valves was similar to that of real valves

The results show that these models can accurately show which patients may have blood leakage, and even show the location and severity of such complications. "The results of this study are very encouraging. Even though valve replacement surgery is quite mature, in some cases, using a valve of different size or a different manufacturer can improve the efficacy, and 3D printing will be able to determine which is the most appropriate," the researchers said.

They plan to continue this project, evaluate the use of 3D printed valves as a preoperative planning tool, test more models, and find new methods to analyze test results.

"Finally, once the patient has performed CT scanning, we can create a model, try different types of valves on it, and tell the doctor which is most effective," said the researcher. "We can even predict that a patient may have moderate perivalvular leakage, but a balloon dilatation can solve this problem."